Quantum materials, a fascinating class of materials that harness the power of quantum mechanics, are revolutionizing modern science and technology. Quantum materials often possess exotic states of matter, such as superconductivity or magnetic ordering, that defy conventional understanding and can be manipulated for various technological applications. To further enhance and manipulate the intriguing characteristics of quantum materials, researchers leverage nanostructuring—the ability to precisely control the geometry on the atomic scale. Specifically, nanostructuring provides the ability to manipulate and fine-tune the electrical and thermal properties of quantum and other materials. This can result, for example, in designer structures that conduct current very well, but impede heat transport. A related critical challenge for a broad range of nanotechnologies is the need for more efficient cooling so that the nanodevices do not overheat during operation. To better understand heat transport at the nanoscale, JILA Fellows Margaret Murnane, Henry Kapteyn, and their research groups within the STROBE NSF Center, JILA, and the University of Colorado Boulder, created the first general analytical theory of nanoscale-confined heat transport, that can be used to engineer heat transport in 3D nanosystems—such as nanowires and nanomeshes—that are of great interest for next-generation energy-efficient devices. This discovery was published in NanoLetters.

Harnessing Geometry

Understanding heat flow within the nanostructures of quantum and other materials unveils fundamental insights into thermal transport and paves the way for developing advanced thermoelectric devices and more efficient heat management systems. Thermoelectric materials can convert waste heat into useful electrical energy or regulate temperature differentials in electronic components. As Joshua Knobloch, a JILA and STROBE postdoctoral research associate, explained, “The main motivation for our work is the need for better thermal management strategies, which are very important for many devices, as the operating temperature of devices often determines their efficiency. For example, the rate at which a computer can do computations has been limited for about two decades because computer chips overheat. So, finding ways to increase heat dissipation, or to tailor the heat flow, is critically important.”

To boost heat dissipation in these materials, Knobloch and graduate student Brendan McBennett highlighted two main strategies. “One option is to change the material composition of your device, that is, find a material with optimal thermal properties,” stated Knobloch. While this strategy can boost the heat dissipation of a quantum material, it can also constrain other properties that this material may possess. Knobloch added, “Another option is nano-structuring, where you change the system's geometry while maintaining the composition. And because the structuring occurs on such a small scale, the geometry influences the fundamental physics at play, implying that you can tailor it for specific physical properties.” For example, graphene, a well-known quantum material, is geometrically structured in flat hexagonal lattices. The structure of these lattices is what simultaneously gives the material high tensile strength, stability, and thermal conductivity.

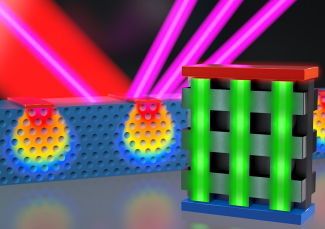

Similarly, Knobloch and the other researchers wanted to understand how the geometry, or nano-structuring, of a common electronics material, such as silicon, influences heat dissipation. Knobloch elaborated that “We studied silicon, which is widely used in electronic devices. Specifically, the device was a nanostructured metalattice, containing periodically arranged holes carved out of solid material on a very small scale, a 10-nanometer scale, hundreds of times smaller than the thickness of a red blood cell.”

Collaborators at Pennsylvania State University fashioned the nanostructured silicon material for the study. To understand the heat dissipation within the material, the researchers probed the silicon material with powerful extreme ultraviolet (EUV) lasers to observe heat flow within the material. “After laser-heating these metal structures, the heat is transported out of the metal structures and flows through the material below,” elaborated Knobloch. “With the EUV probe, we are able to look at how the surface deforms. As the material heats up, it expands, and we observe the dynamics with our EUV laser with very high sensitivity to see how the material is deforming as the structure is cooling. Probing the heated metal structures as they cool down can tell us how the heat flows through the nanostructured material. That, in turn, can inform us on the fundamental behaviors within the system.”

Following the (Heat) Flow

Historically, scientists thought nanoscale heat flowed away from a hot structure in straight lines under highly confined heat transport conditions, a property known as ballistic conduction or ballistic transport “It is common to think of phonons, the quantized vibrational energy packets responsible for thermal conduction in a material, as particles which travel ballistically, that is that they move in straight lines like pool balls bouncing around inside this material,” Knobloch stated. Instead, the researchers took a more nuanced approach. “We consider heat to move hydrodynamically, a picture analogous to flowing water, where the heat flow adapts to the entire geometry of the structure and can flow in and out and around these pores,” added Knobloch.

The researchers proposed a theoretical model of heat dissipation mimicking hydrodynamic effects, with collaborators from the University of Barcelona including Albert Beardo, who is now at the University of Colorado Boulder. In an exciting discovery, this new model not only explained the study’s results but also a wide range of data taken on different nanostructured silicon devices. “We found that when you take this hydrodynamic approach, you can derive a theory that could explain a broad range of experiments and predictions throughout the literature,” stated Knobloch. “We took not only the data we measured with our EUV technique but also data from other studies in the literature, where we found that using this hydrodynamic perspective, thinking about heat flowing like water, we can explain a very broad range of these nanostructured materials, which has been out of reach for analytical theories for a very long time.” These materials include things like nano-meshes, nanowires, and metalattices, all of which can be fine-tuned to exhibit specific properties.

Even with the varying geometries of these materials, the researchers found they had similar hydrodynamic-like heat flow behaviors. “We do not yet understand why we are observing this universal behavior,” Knobloch said. “Essentially, all of these systems contain an intrinsic phonon property called viscosity, which depends only on the material’s porosity in a precise way. In other words, the ratio of air versus silicon [for this specific experiment] alters some intrinsic physics independent of the precise geometrical shape, and this is a deep concept we don't yet understand.” As researchers leverage the different nanostructured geometries of all of these quantum materials, understanding the underlying relationship between geometry and heat flow can give a boost to creating these materials.

Written by Kenna Hughes-Castleberry, JILA Science Communicator